Need help with your application? Contact us for expert advice.

Able Instruments can assist you and your customers in the following areas:

- OEM application guidance: Support selecting the correct series and configuration for low-pressure fluid and gas systems.

- Valve integration support: Assistance with porting, mounting and integration into OEM manifolds and control assemblies.

- After-sales and lifecycle support: Guidance on ordering information, replacement valves and maintaining long-term system reliability.

Further to the above, Able can offer customised solutions based on your individual requirements. Email us now at info@ableinstruments.com

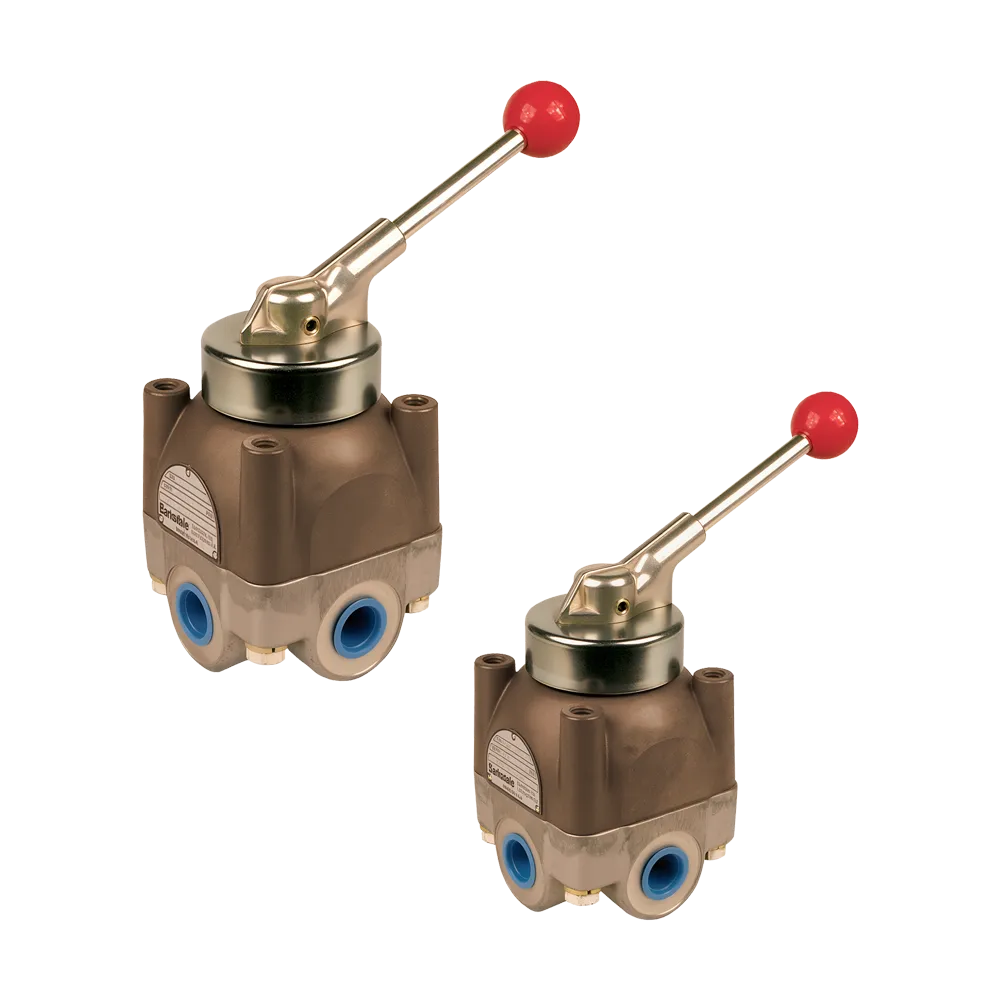

Barksdale Low Pressure OEM Valves

Shear-Seal® directional control valves for low-pressure fluid and gas OEM systems

Able Instruments offer the Barksdale Low Pressure OEM Valve range for reliable directional control in low-pressure fluid and gas systems. This product family includes Series 9040 and 9080, developed specifically for original equipment manufacturers requiring compact, configurable valve solutions.

The Low Pressure OEM Valves are based on Barksdale’s proven Shear-Seal® operating principle, utilising a rotating rotor and stationary seal to provide positive shut-off and low internal leakage. Compared with conventional spool-type valves, the Shear-Seal® design offers improved tolerance to contamination, supporting dependable operation where fluid cleanliness cannot always be guaranteed.

Key Features:

- Low-pressure directional control: Designed for reliable operation in fluid and gas systems up to approximately 500 psi.

- Shear-Seal® operating principle: Rotating rotor and stationary seal provide positive shut-off with low internal leakage.

- Fluid and gas compatibility: Suitable for use with gases and hydraulic fluids in low-pressure OEM applications.

- OEM-focused design: Compact construction supports efficient integration into custom equipment and control assemblies.

- Contamination tolerance: Shear-Seal® technology maintains consistent performance where fluid cleanliness may vary.

- Multiple series options: Series 9040 and 9080 provide flexibility in porting style and mounting orientation.

- Low maintenance requirements: Proven valve design reduces wear compared with conventional spool-type valves.

Have a particular project in mind? We’d welcome a call on +44 (0) 1189 311 188

Designed for operation with gases and hydraulic fluids, these valves support working pressures up to 500 psi depending on configuration. Flexible porting options and compact construction allow efficient integration into OEM manifolds, control panels and pilot circuits where space, reliability and repeatable performance are critical.

Typical applications include OEM machinery, pneumatic control systems, pilot circuits and low-pressure hydraulic applications requiring consistent directional control and long-term operational reliability.

Low Pressure OEM Valves Specifications:

Valve Type | Shear-Seal® directional control valve |

|---|---|

Series | 9040, 9080 |

Operating Medium | Gases and hydraulic fluids |

Maximum Working Pressure | Up to 500 psi (34 bar), depending on configuration |

Proof Pressure | Approximately 1.5 × rated working pressure |

Burst Pressure | Approximately 2 × rated working pressure |

Back Pressure Limitation | Return port back pressure should not exceed approximately 250 psi (17.2 bar) |

Porting Configuration | Side ported (9040) or straight / bottom ported (9080) |

Mounting Style | Direct mounting or manifold mounting, depending on series |

Operating Temperature | –40 °C to +121 °C (–40 °F to +250 °F) |

Construction Materials | Aluminium housing and rotor with elastomer seals, configuration dependent |

Note: Specifications may vary depending on the selected series, model code and configuration. Options may include different porting styles, mounting arrangements, flow patterns and seal materials. Please refer to the ordering information or contact Able for guidance on selecting the correct low pressure OEM valve for your application.