The flagship model in this range is the Universal IV Water Cut Meter, which offers continuous measurement of water content in crude oil, condensate, or refined product pipelines. With a rugged inline or insertion sensor, the device delivers reliable 4–20 mA output and integrates easily into control systems. The addition of the Density Compensation Module further refines accuracy when fluid composition or ambient conditions fluctuate.

Designed for use in refineries, tank farms, oilfields, separators and lease automatic custody transfer (LACT) skids, Drexelbrook water cut systems provide operators with real-time visibility of process efficiency and product quality.

Key advantages include:

- Minimal maintenance

- Simple calibration

- Inline and insertion mounting options

- Repeatable accuracy in changing process conditions

- SIL2 certification and hazardous area approvals

As AMETEK Drexelbrook’s Exclusive UK and Ireland Representative, Able Instruments can advise on system selection, installation and integration, and offer support services tailored to your process needs.

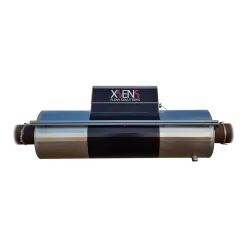

Additional Clamp-On Option from XSENS

In addition to Drexelbrook’s inline RF admittance systems, Able also supplies clamp-on ultrasonic water cut solutions from XSENS. Their XACT range offers non-intrusive measurement from outside the pipe, ideal for brownfield installations or sites where process shutdown is not an option.

XSENS products include:

- XACT Clamp-On Water Cut Meter: Continuous 0–100% water-in-oil monitoring using multi-path ultrasonic transmission

- XACT Clamp-On Liquid Flow Rate & Water Cut Meter: 2-in-1 system providing simultaneous flow rate, water cut and calculated net oil/water outputs

XSENS’ clamp-on approach avoids pipe cutting or welding, requires no straight-run lengths, and minimises installation time with no process interruption which is particularly useful on offshore platforms, production facilities, and retrofit conditions.