The meter’s natural ability to measure true mass flow directly, along with its characteristic linearity and accuracy, makes Coriolis ideally suited for custody transfer / fiscal applications.

Unaffected by pressure, temperature, viscosity and offering high levels of precision, make the technology ideal for critical applications in industries such as pharmaceuticals, food and beverages, and chemical processing / oil & gas.

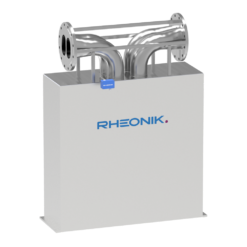

Rheonik’s Omega design further augments the superiority of Coriolis technology by facilitating increased tube wall thickness for high pressure (full design pressure without secondary containment) and higher temperature applications. The higher wall thickness also provides long-term stability and safety margin against potential abrasion and corrosion.

Rheonik are the world leader in high pressure meters for Hydrogen dispensing. From the very outset, Rheonik has worked with all major hydrogen suppliers to produce accurate flow meters which expertly manage the extremely high pressures associated with hydrogen distribution and dispensing. Rheonik Coriolis mass flow meters play a major role in ensuring energy from renewable energy sources remains part of our day-to-day energy makeup.

Quick Select Application Guide:

Technical Data Verified by:

Dave Quelch

– Head of Marketing & Business Development (InstMC).

Able Instruments is the Exclusive UK & Ireland Sales and Service Partner for Rheonik Messtechnik GmbH.

Frequently Asked Questions: Rheonik Coriolis Technology

Can Rheonik Coriolis meters be used for Hydrogen dispensing?

Yes. Rheonik RHM series meters feature a patented Omega tube design capable of handling extreme pressures up to 1722 bar. This makes them fully compliant with OIML R139 standards for hydrogen refueling stations, where standard U-tube meters may suffer from tube rupture or stability issues.

Does Able Instruments offer calibration for Coriolis meters?

Yes. As the exclusive UK partner, Able provides cradle-to-grave support including commissioning, UKAS-traceable calibration, and long-term service. We operate local calibration rigs capable of verifying mass flow performance to ensure ongoing regulatory compliance.

What is the advantage of the Rheonik Omega tube design?

The Omega shape eliminates the stress points found in traditional bent-tube meters. This allows for thicker tube walls (higher pressure ratings up to 1722 bar) and superior resistance to vibration and torsion, ensuring high accuracy (0.05%) even in demanding offshore or high-pressure chemical injection applications.

Industrial production uses a variety of complex measurement instrumentation devices to monitor and control the manufacture and quality of goods and materials. However, some of the most advanced tools rely solely on basic principles of physics. A Coriolis Mass Flow Meter is a good example of this – although there is a considerable amount of physics going on inside the instrument, it isn’t as complicated as you might imagine.

Industrial production uses a variety of complex measurement instrumentation devices to monitor and control the manufacture and quality of goods and materials. However, some of the most advanced tools rely solely on basic principles of physics. A Coriolis Mass Flow Meter is a good example of this – although there is a considerable amount of physics going on inside the instrument, it isn’t as complicated as you might imagine.